FCT ACTech appoints SCANMAT as official agent for Poland

We are pleased to announce our cooperation with SCANMAT, who will serve as our official sales and service agent in Warsaw, Poland. This partnership is a strategic step forward in enhancing customer experience, ensuring faster response times, and offering expert local support for our Polish customers.

With over 25 years of experience in international business management, advanced X-ray and neutron engineering, and customer support in industrial and R&D sectors, SCANMAT brings a wealth of expertise and a strong commitment to customer-centric service.

Their mission to deliver real value to both industrial production and scientific research aligns closely with FCT ACTech’s goals. By focusing on integrity, effectiveness, and growth, SCANMAT continues to be a trusted partner in the fields of material and nanomaterial analysis and production process control.

We are confident that this cooperation will bring significant benefits to our customers and partners in Poland, reinforcing our shared commitment to innovation, service excellence, and long-term success.

phone: +48 601 667 971

email: support@scanmat.pl

SCANMAT Sp. z o.o.

- Zwoleńska 102D

04-761 Warszawa

Poland

NEW ALLIANCE: COMAST and FCT ACTech

FCT ACTech is proud to announce its new partnership with COMAST Group—an alliance that brings together decades of expertise in material analysis and process optimization. COMAST, which includes the companies Comast, Symtek, and Xamtec, delivers advanced solutions across a wide range of industries such as cement, mining, metals, polymers, and hydrocarbons in South America. Renowned for their excellence in X-Ray Spectrometry, COMAST is committed to developing and sharing applied knowledge that drives quality and efficiency in industrial processes.

Through this partnership, FCT ACTech and COMAST will jointly support customers in:

- Enhancing process optimization and quality control

- Advancing environmental monitoring

- Reducing waste and increasing recovery rates

- Achieving fuel and energy efficiency

- Lowering operational and labor-related costs

Together, our teams offer a full-scope approach—from sample collection and preparation to analysis and metrological validation of results. In addition to state-of-the-art analytical instruments, COMAST provides tailored training and consulting services, backed by their own X-Ray Fluorescence and Diffraction laboratory in Bogotá, Colombia.

With over 30 years of experience, COMAST’s technical expertise and customer-centric approach make them a trusted partner for improving quality assurance, material analysis, and process control. This collaboration reinforces both companies’ commitment to delivering innovation and measurable value to customers in Americas.

FCT ACTech appoints Ray On Systems & Control as official agent in India

FCT ACTech, the leading global provider of on-line XRF and XRD analytical instruments for the minerals and cement industries, is proud to announce the appointment of Ray On Systems & Control as its official agent in India.

This strategic partnership marks a significant milestone in expanding FCT ACTech’s presence across the Indian subcontinent, with the goal of enhancing customer engagement and accelerating the sales process in this key market.

About Ray On Systems & Control

Established in 2021 under the banner of Ray On Instruments, Ray On Systems & Control was founded by a team of visionary engineers and technocrats with decades of combined industry experience. Headquartered in India, the company has a strong focus on providing specialized after-sales service support for the Cement, Steel, and Mineral industries—particularly in remote and underserved regions.

As India’s industrial sector continues to grow and modernize, the demand for precision instrumentation and automation solutions has never been higher. In response, Ray On Systems, in partnership with FCT ACTech (a division of FCT International), is bringing cutting-edge online and at-line XRF/XRD analyzers to the Indian and neighbouring markets.

With a dedicated team of sales professionals, product specialists, and service engineers, Ray On offers full end-to-end support—from sales to installation and after-sales service. The company is committed to delivering cost-effective, high-performance solutions that improve efficiency, reduce energy consumption, and support sustainable practices.

Shared Mission and Vision

This collaboration is driven by a shared mission to deliver high-quality products, world-class service, and seamless customer experiences. Ray On’s vision to become the preferred leader in X-ray analysers for quality and process control aligns perfectly with FCT ACTech’s commitment to technological innovation and customer-centric solutions.

Ray On Systems & Control

Website : www.rayonsc.com

Contact : +91- 9831054105

OPTIMUM UTILISATION OF ENERGY RESOURCES

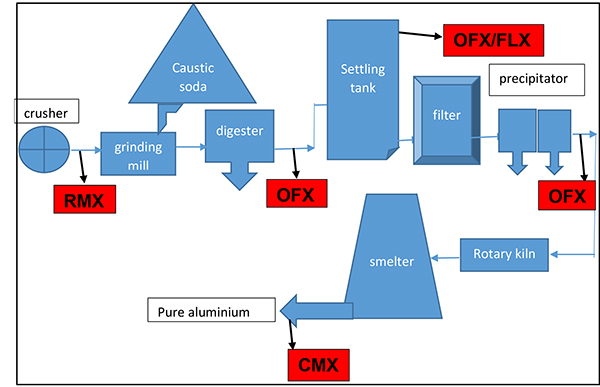

OPTIMUM UTILISATION OF ENERGY RESOURCES AND REDUCING CO2FOOTPRINT USING ON-LINE ANALYSER IN ALUMINIUM PRODUCTION PROCESS

Presentation made by Tamal K. Ghosh1, Primal Chakraborty1and Roger Meier2

1ICON Scientific Systems, Kolkata, India 2FCT ACTech Adelaide, Australia

Introduction of a new HRF measurement concept called HRTC

HRTC XRF ™stands for high-resolution real time continuous X-ray fluorescence.

The availability of highly efficient, compact, solid-state energy dispersive XRF detectors opened the opportunity to build on-line x-ray systems, where the sample is presented on a continuous moving support plate to the x-ray beam and simultaneously the relevant x-ray response signal is collected.

The compact design of the beam path completes the set-up for high obtainable count rates.

“Wiser with ANALYSERS”, Dr.-Ing. Roger Meier, FCT-Actech

FREE DOWNLOAD

Dr.-Ing. Roger Meier explains why online analysers should form part of every cement plant’s CO2 emissions reduction strategy.

“X-Ray Vision”, Peter Storer, R&D Manager, FCT ACTech. Published in World Cement, July 2019

FREE DOWNLOAD

In “X-ray Vision”, Dr Peter Storer discusses the use of X-ray fluorescence for raw mix control.

Please fill out the form to access your free download of the article.

Improving kiln and quality control

Improving kiln and quality control

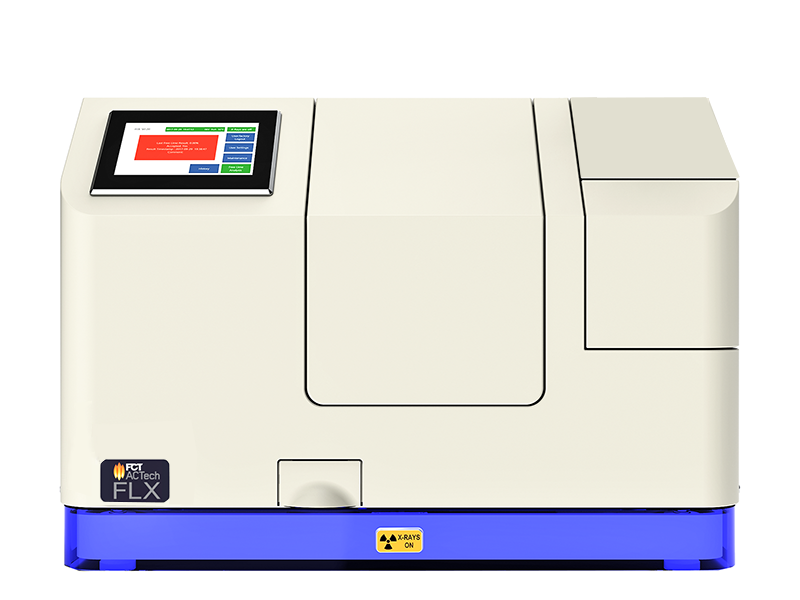

Turn free lime control into your new competitive advantage and improve quality with the X-Series FLX and FLX+ analyzers.

The FLX Free Lime Analyzer delivers accurate and representative analysis of crushed or ground clinker with real-time results every 5 minutes, while FLX+ offers the additional ability to directly measure C3S.

Benefits include:

- Large, highly representative samples (200g or ½ lb) tested every 7 minutes

- Proprietary high-resolution, solid state detector for high speed XRD analysis

- Intuitive and simple to use

- Designed for indoor benchtop use or outdoor continuous online operation

- Powered by ClassX software suite

- Smart, automated process with incorporated:

- Clinker grinder and separate powder inlet

- Large sample preparation robotics

- Ultra-fast detection and analysis

For more information about FLX and FLX+, or to download the brochure, please click here

Successful RMX commissioning in Florida

Successful RMX commissioning in Florida

This month, we successfully commissioned an RMX for a cement plant in Florida, USA. The RMX Raw Meal Analyzer directly measures the elements Ca, Si, Fe, Al, S and Mg and calculates the hypothetical compounds LSF, C3S, C2S, C3A and C4AF.

Designed for post-mill installation, RMX features large sample intake and in-built sample preparation robotics, as well as an EdXRF module with state-of-the-art SDD detector for improved accuracy and repeatability.

Benefits include:

- Highly representative elemental analysis, taking into account recirculating kiln dust

- Incorporates sample preparation robotics and presentation system

- Accurate and repeatable results with virtually ‘zero’ drift

- Large sample size of 50-100g/min (1/4 pound per minute)

- 20 complete data points per hour

- Complete analysis of all major elements (Al, Fe, Si, Ca) plus S, Mg and (optional) Na and K

- Unique post mill installation ensures bias-free material presentation

- Stable, accurate calibration

- Compact size adapts easily to existing plant layouts

- Smart design for ease of use and increased safety

- Industrial grade touchscreen interface for local diagnostics, operation, and control

For more information about RMX, or to download the brochure, please click here

Introducing Roger Meier

Introducing Roger Meier

We are pleased to introduce Dr. Roger Meier, GM Business Development (EMEA & CIS), who has recently joined the FCT ACTech team.

Roger brings a wealth of experience, having most recently been the Business Development Director for Sampling and Preparation at FLSmidth, with previous experience at companies such as PANalytical.

Roger holds a PhD in Materials Science from University of Erlangen, Germany.

Based in the Netherlands, Roger leads our European office and is contactable via:

Email: roger.meier@fctinternational.com

Phone:(+31) 682-523-012

RMX delivers results

RMX Delivers Results

The first RMX analyzer for raw mix control was commissioned in December 2018 for a plant in Alabama, USA. RMX analyzes raw meal with elemental data updates every 2 minutes, with the real time data stream enabling frequent raw mix feeder adjustments in kiln feed LSF and C3S variation.

Since commissioning, the plant has reported excellent results achieved through the at-line installation of the RMX. Raw meal variation has been reduced by 44%, resulting in significant improvement to kiln feed variability, while clinker free lime variability has also been measurably reduced.

“The kiln operators report that the mix is easier to burn, and the kiln is easier to control,” a representative said.

“Before we had to target a lower C3S to assist with kiln operation, now we can target 63-64 and achieve higher early strengths.”

The RMX is part of FCT ACTech’s X-Series range which includes a suite of analyzers for raw mix, clinker quality and cement blends control, as well as elemental and mineralogical analyzers for the mining and mineral processing industries.

The X-Series range is the next generation evolution from the same patented technologies that propelled the Continuous On-Stream Mineralogical Analyzer (COSMA) to the forefront of process control technologies 20 years ago.

To learn more about the X-Series range, please click here

In The Press

The new FLX free lime analyser was presented at the 60th annual IEEE-IAS/PCA Cement Industry Technical Conference held in Nashville, Tennessee, USA during May 2018. The conference is the largest of its kind for the cement industry and draws over 700 delegates worldwide.

Delegates had a first hand opportunity to explore the simplicity of the game-changer FLX unit and to discuss potential plant savings.