Optimize your cement process

Reduce operating costs by decreasing fuel consumption and product variation. Extend refractory life and improve cement quality by having better control.

FCT ACTech offers a complete line of analytical instruments, ancillary equipment and end-to-end solutions to help cement producers improve product quality, boost efficiency, lower productions costs, and create safer and greener production lines.

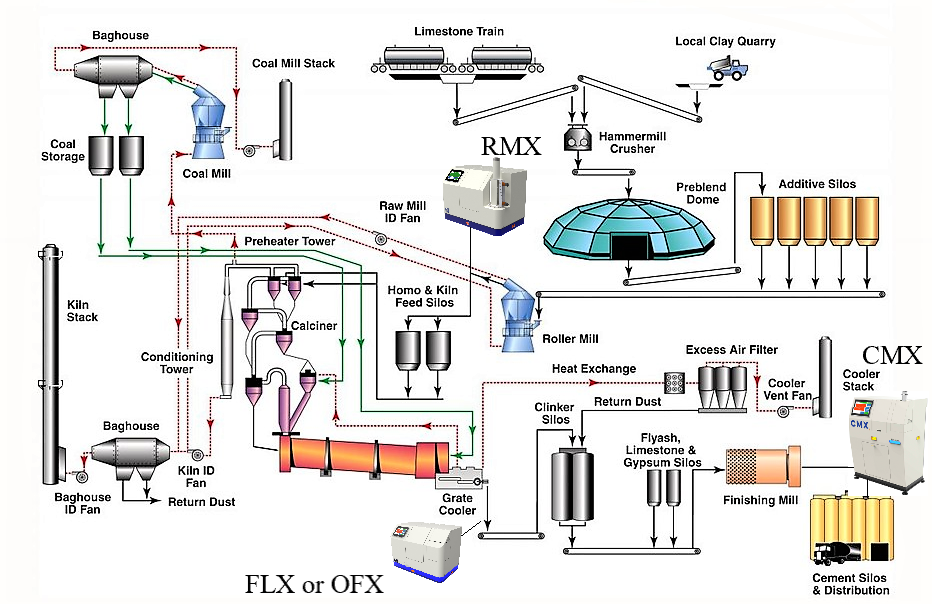

The RMX instrument controls raw meal chemistry and provides feedback to your existing cross-belt analyzer, or can directly send the information as an input into a raw mix proportioning software to finely adjust the calcium carbonate, silica, alumina and iron ore.

Gaining control with under or over burning the clinker provides a host of benefits. To do so free lime must constantly be monitored Currently, most plants use wet methods or lab XRD instruments to get their free lime results every two to four hours. That frequency often misses many changes that happen in your kiln. The X-series FLX allows you to measure clinker free lime and trend better for tight control in order to avoid any excursions that translate into unnecessary expenses.

The X-series OFX has all the features of the FLX but it can also monitor all major elements which is fundamental when burning different fuel mixes, especially alternative fuels.

The CMXγ advanced on-stream XRD mineralogical analyzer is simply the instrument of choice for cement blends controls, allowing producers to maximize gypsum, limestone, slag or flyash additions.