POWDER SAMPLERS

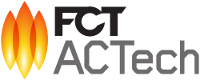

A. SamPX1 PISTON SAMPLER

The piston sampler SamPX1 is installed perpendicular to the direction of material flow. At a predetermined frequency, the sampler control system will, activate the pneumatic ram from its rest position inside the discharge body, clearing any old sample in the sample tube. Sample is then collected via the special cut openings and the pneumatic ram is retracted which then discharges the sample into the sample collecting pipe. One (1) adjustable timer is included in the control system to control the duration of the ram in the sampling position to manage the quantity of sample collected.

Diameter of the sample collecting pipe: Ø 50-75 mm /2-3 inch (Depending on configuration)

Sample volume approx. 130-150 dm³/h. Maximum stroke frequency – once/minute (60 times per hour)

Weight: 20-22kg /44-49lbs

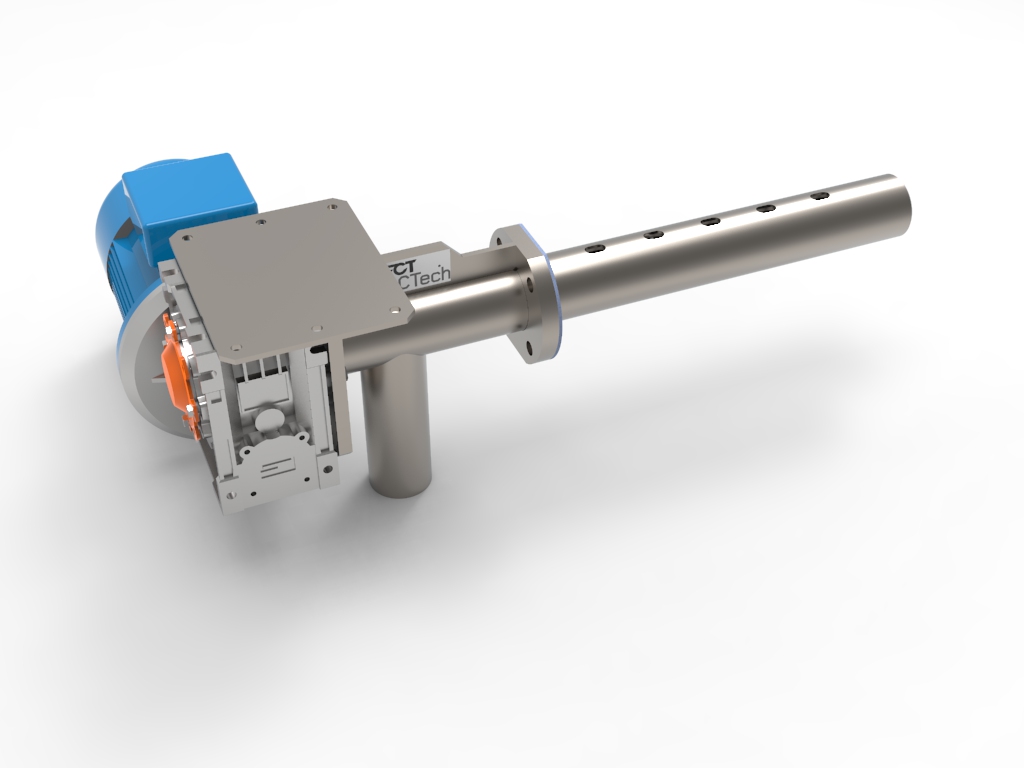

B. SamSX1 SCREW SAMPLER

The screw sampler SamSX1 is installed perpendicular to the direction of material flow. At a predetermined frequency, the sampler control system will start the screw in reverse to clear any old material, then will change the screw direction and collect sample, via the special cut openings, which is then discharged into the sample collecting pipe. Two (2) adjustable timers are included in the control system to control the cleaning time and sample time in order to ensure fresh sample is collected and to manage the quantity of sample collected.

Diameter of the sample collecting pipe: Ø 50-75 mm /2-3 inch (Depending on configuration)

Sample volume configurable using the adjustable timers. When run continuously, sample volume approx. 130-150dm3/h

Weight: 20-22kg /44-49lbs

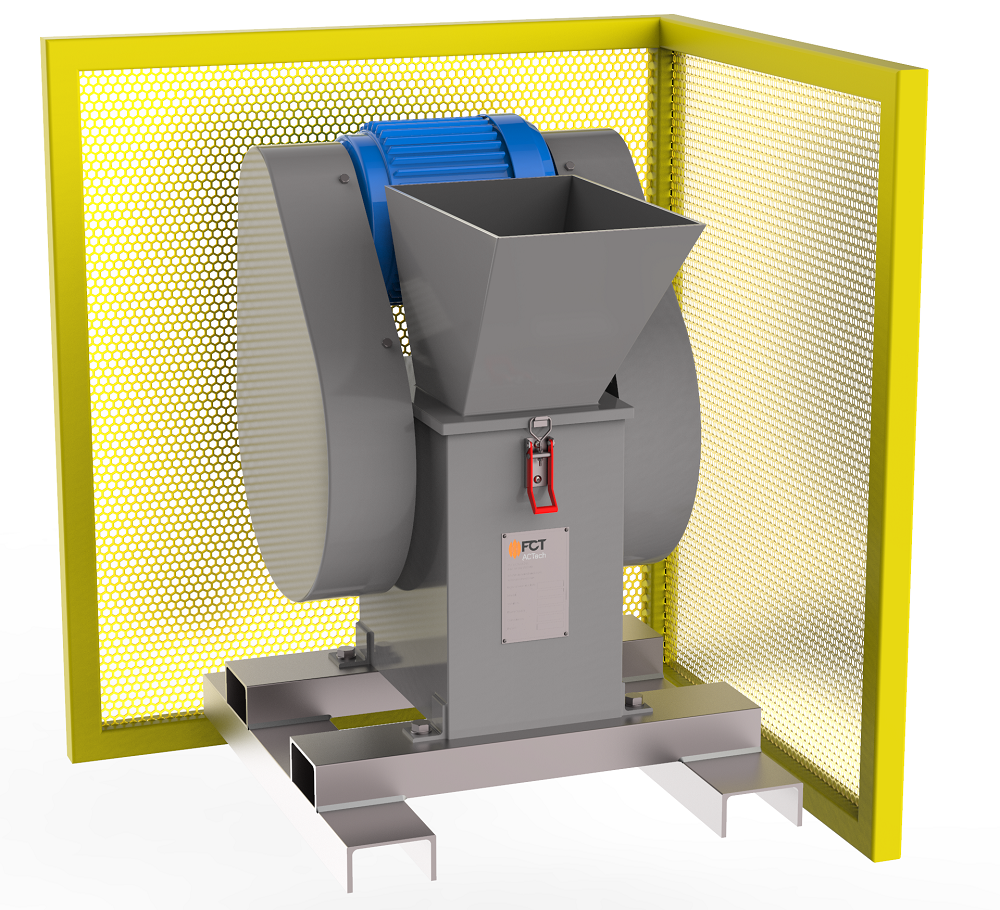

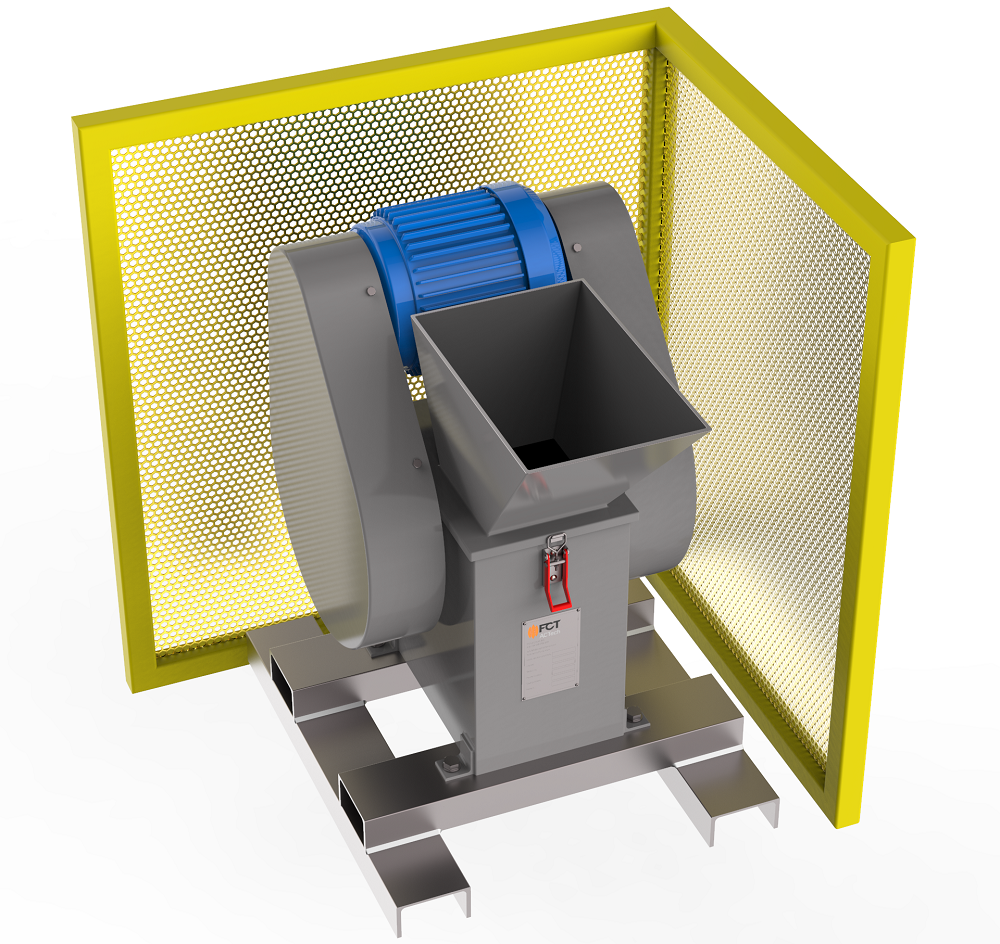

JAW CRUSHER

The jaw crusher JCX1 is designed to give long life and excellent performance. The combination of Flat Faced Pulleys as supplied with V-belts on the crusher was a specially engineered arrangement for this machine. This combination has proven to be the very best arrangement for machines such as these.

Capacity: 590 Kg/ 1300 lbs (per hour)

Jaw Capacity: 12.7cm x 17.8cm (5″ x 7″)

Reduction Size: 0.3cm/ 1/8″ (minimum) to 2cm/ 3/4″ (maximum)

RPM :400

SLURRY DRYER

The SDX1 dryer is designed for continuously drying slurry material (for mining applications). The Drier consists of an electrically heated rotating steel plate contained within an insulated oven body. Product feed pipe is located in roof panel and dried product chute exits the base. A scraper blade and screw conveyor moves the dried product from the rotating steel plate (turntable) to the exit chute. The scraping force can be adjusted by the external spring loading assembly. Removable hatches and multiple view ports are provided for viewing of process and access for cleaning. Two Drain port are also provided in the base to handle any over feed of product. An Exhaust fan and Fresh Air inlet port are provided to remove the evaporated product from the oven. Additional ports are located in the roof panel for installation of other temperature control or monitoring devices if necessary .

Operating Temperature 130°C (Max)

Interior: 316SS

Exterior: 304SS

Insulation: Rockwool 450

Electrical element power: 30-50kW (depending on model)

Power requirement: 400-480V, 3 phase, 50/60Hz (depending on region)